Tying machine AS 100 S

works on the product to fill with pork natural casing , bovine or derivative casings such as cast casing, collagen or similar, with caliber from 25 to 85 mm, loaded on the filling pipe, in single piece or loose, with semi-curved or straight form.

These products can be tied in continuous, separated with a tiying, or separated with double tiying mode, to have a better drying during seasoning or to have more space between them to cut. A practical exit slide helps the products to come out.

Type of tying: by weight and time

Type of product:

Sausage

Cotechino

Salame

Cooked cured meats

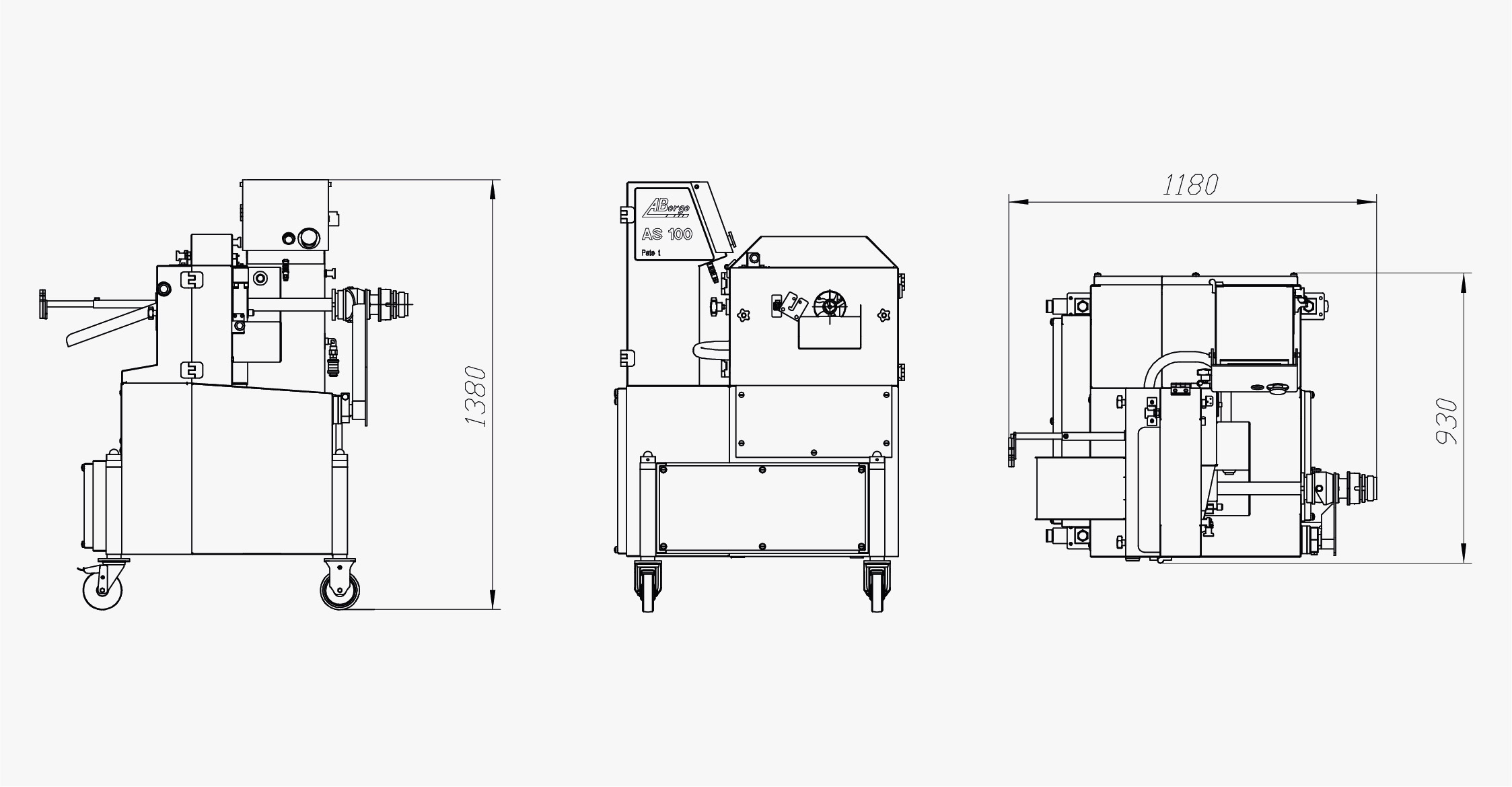

Tying machine AS 100 S

Technical features

| Production: | single or double tying | |

|---|---|---|

| Loop: | length from 80 to 250mm | |

| Spacing: | From 5 to 60 mm | |

| Tying speed: | from 10 to 16 cycles/min (it depends on weight, type of casing, type of filler) | |

| Installed power: | 8kW – 400V – 50Hz 3 phases + N | |

| Weight: | 340kg | |

| Type of casing:: | natural, artificial | |

| Products caliber: | 25-85 mm | |

Automatic casing spooler AS 32

Loop formation system

Request informations

* required fields

Borgo is the right choice for your activity:

request now your personalized quote!