Tying machine AS 3.1

AS 3.1 an innovative project of synchronized tying machine suitable to tie salami and other cured meats. The simplicity and practicity make this machine suitable for small and medium food industries. The versatility is a strength point planned by azienda BORGO 1988 staff. It is possible to tie cured meats with fixed weight by setting it through the filler or though the tying machine’s control panel, the production speed depends on product’s weight.

Why it is distinguished:

- All the parameters can be simply set on the Touch-Screen control panel which has an intuitive layout.

- Easy to move thanks to the 4 wheels adjustable in height, it is also equipped with an electric box completely closed in stainless steel to isolate all the electro-pneumatic connections.

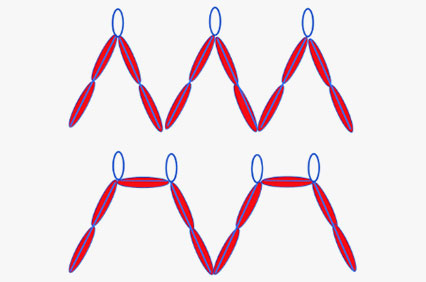

Type of tying: tying by weigh, tying by time

Type of product:

Curved sausage

Sausage

Cooked cured meats

Salame

Cotechino

Tying machine AS 3.1

Technical features

| Electrical supply: | 230 Volt | |

|---|---|---|

| Pneumatic supply: | 6 bar - consumption: 9lt/min | |

| Tying laps: | from 2 to 10 | |

| Production speed: | up to 100 cycles/min | |

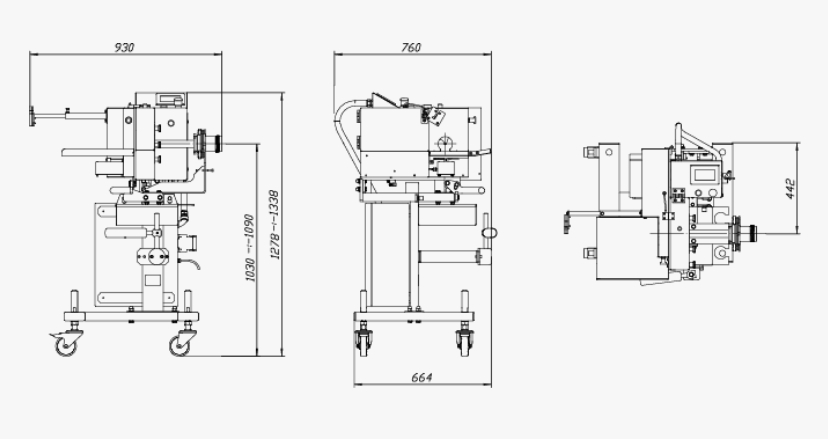

| Working table height: | from 1000 to 1100 mm | |

| Weight: | 122 kg | |

| Type of casing:: | natural, artificial | |

| Products caliber: | 25-65 mm | |

TYING

TYPES OF THREAD AND CASING

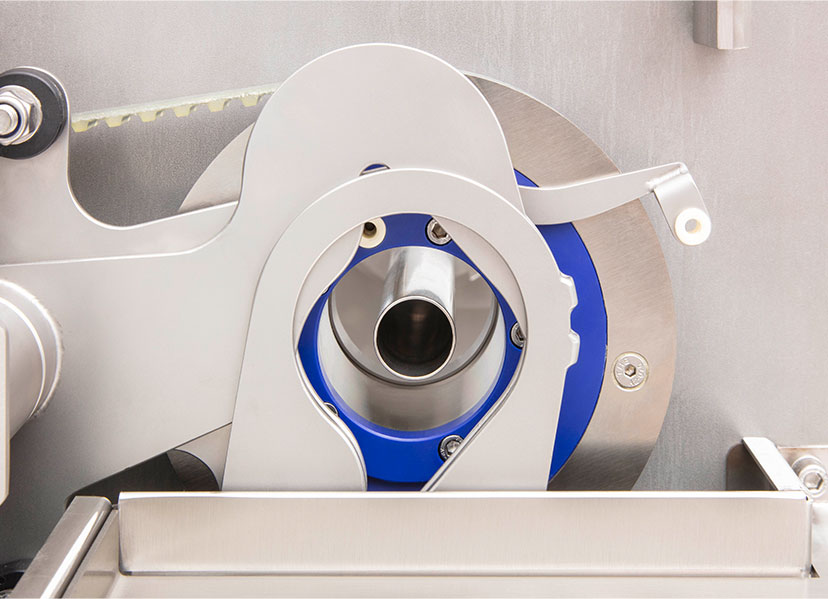

The plier’s hole dimensions permit to tie products with caliber up to 65 mm and with different types of casing: natural of pork or bovine, cast casing, collagen or similar. The plier’s closing hole adjustment can be done through the millimetrical manual registration. Moreover, thanks to the loop formation system and thanks to the wide exit slide, it is possible to tie curved sausages.

We decided to equip the AS 3.1 with a bowl for natural casing, placed under the filling pipe, which guarantees a pratical production. This permits to keep all the mainly used accessories nearby. Moreover. the machine’s start is controlled by knee lever so that the operator can keep his hands free to manage the casing and to pull the product.

This model of tying machine is synchronizable with all the continuous vacuum fillers on the market. The screw junction ensures a rapid and safe fixing, while the connection between the two machines is done through impulses’ cable. The filling pipe’s length of 370 mm guarantees the possibility to use different lengths of casing and doesn’t change product’s quality. Casing loading is easier thanks to the practical machine opening by manual lever.

Request informations

* required fields

CHOOSE THE MOST SUITABLE TYING MACHINE FOR YOU:

CHOOSE THE MOST SUITABLE TYING MACHINE FOR YOU: